Perlita y Vermiculita has developed different systems for fire protection for the chemical and petrochemical industries. These specialised environments work with highly flammable products and as such, the risks of explosion or fire(s) are exponentially greater.

In addition, studies and historical data from real fires have demonstrated that these fires ignite and spread much faster than in normal situations.It is imperative that the right fire protections are in place.

One of the main measures taken in the chemical and petrochemical industry is the simulation of a fire curve which is more aggressive than that used in construction. Studies and data from real fires have shown that these industrial fires develop much faster than normal characteristics fires.

Currently there are different models that simulate this behaviour. The most prominent are the NPD (Norwegian Petroleum Directorate), developed in Europe, and the curve UL 1709 (Rapid Rise Fire), developed in the United States. Both curves can be used as test curves for the certification of passive protection products in the chemical and petrochemical industry.

A high density, exterior grade, heavy duty, cementitious fireproofing material ideal for use in industrial and petrochemical environments.

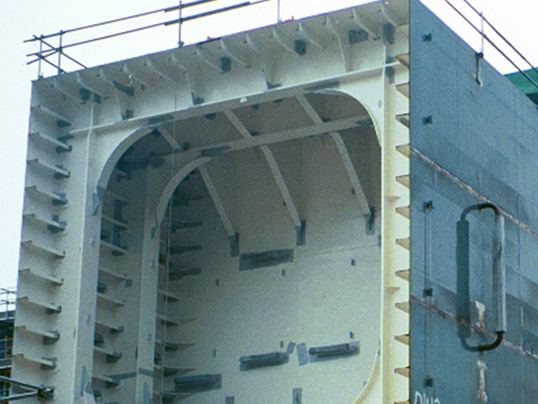

Provides1 to 4 hour(s) of fire protection for structural steel, vessel skirts, bulkheads, LPG vessels, LNG terminals or to upgrade the fire resistance of existing concrete.

Suitable for both field and shop applications when applied by our published application procedures. The superior physical properties of Pyrocrete 241 promote high durability when handling, during construction, and while in service.